Have you ever wondered how companies know how long a task should take? That’s where Standard Allowed Minutes (SAM) come in. It’s a common term used in factories and industries, especially in the United States, to set fair and efficient work times. This article will explain it all in a simple way.

What Does Standard Allowed Minutes Mean?

Standard Allowed Minutes, also known as SAM, refers to the amount of time that should reasonably be allowed to complete a task using standard methods, tools, and working conditions. It’s a time measurement unit used in industries to help estimate labor requirements, costs, and performance.

For example, if a worker in a clothing factory needs to stitch a shirt, the SAM will define how many minutes it should take under normal working conditions. This doesn’t mean rushing the worker; it means giving a fair and accurate measure of how long the job should take. The idea is to keep work efficient and fair for both the company and the workers.

Why Do We Use Standard Allowed Minutes?

Standard Allowed Minutes are used to improve productivity, plan operations, and set fair wages. Without SAM, businesses would struggle to manage time, labor, and costs.

Let’s say you own a sewing factory. If you don’t know how long it takes to sew one pair of jeans, how can you tell if your workers are doing well or falling behind? SAM gives a clear and fair benchmark. It also helps in costing, pricing, and deciding how many workers are needed.

Moreover, when businesses pay by piece rate, SAM helps set a fair rate per item. It ensures workers aren’t overworked or underpaid. This system is used globally, especially in countries like the United States where manufacturing and labor management need exact planning.

How Is Standard Allowed Minutes Calculated?

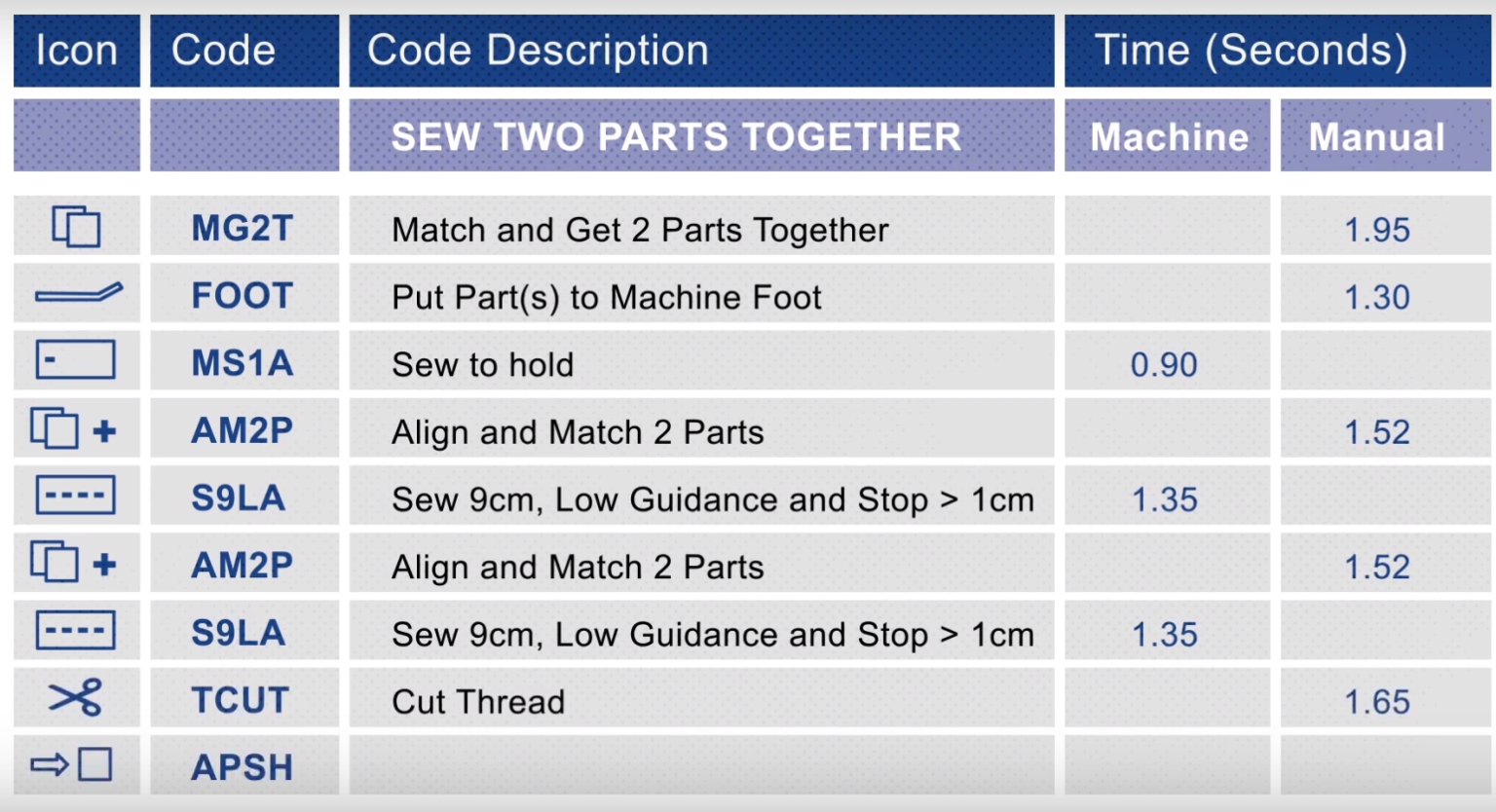

Calculating SAM involves more than just using a stopwatch. It requires a detailed process to make sure the timing is fair and considers all parts of a task. The calculation includes studying each step, timing it, and adding allowances for fatigue, delays, and personal needs.

Let’s break it down:

Breaking Down the Task

The first step is to split the job into smaller tasks. For example, making a shirt can be divided into cutting, stitching, buttoning, and finishing. Each of these has its own time requirement.

Experts observe workers doing each part of the job using the correct methods. They record everything, from how the worker moves to how tools are used. This detailed breakdown ensures every part of the job is accounted for.

Timing Each Step

After breaking down the task, the next step is timing. Trained analysts use a stopwatch or time-tracking software to record how long each part takes. But they don’t just use one time. They take the average of several observations to avoid errors or extremes.

Also, analysts rate the worker’s speed and effort. If someone is working faster or slower than average, adjustments are made to reflect what a “normal” pace would be. This gives a more accurate and fair SAM.

Adding Rest and Delay Time

People are not robots. We all need short breaks, and sometimes small delays happen. So, extra time is added to account for this. This includes time for rest, going to the bathroom, or dealing with minor issues like tool problems or small delays in getting materials.

Usually, around 5% to 20% of the total task time is added as an allowance. This makes the Standard Allowed Minutes realistic and humane.

Examples of Standard Allowed Minutes in Real Life

Let’s look at some real-world examples to see how SAM is used:

- Garment Industry: Stitching a basic T-shirt may have a SAM of 6 minutes. That means a skilled worker should take around 6 minutes using standard tools and methods.

- Shoe Manufacturing: Attaching the sole to a shoe might be set at 3.5 minutes.

- Electronics Assembly: In a factory where phones are made, placing a battery in a phone might have a SAM of 0.8 minutes.

- Automotive: Installing a car seat in a vehicle on the assembly line could have a SAM of 2.5 minutes.

These values help managers plan daily production targets and calculate costs.

Benefits of Using Standard Allowed Minutes

There are many advantages of using SAM in industries:

- Better Planning: SAM helps managers plan how many people are needed and how long production will take.

- Fair Wages: Workers are paid fairly based on the amount of work they do. SAM ensures they’re not underpaid or overburdened.

- Increased Productivity: With clear expectations, workers can focus better, and companies can spot where time is being wasted.

- Cost Management: Businesses can control costs more easily when they know how much time tasks should take.

- Work Measurement: It helps in comparing actual performance with expected performance. This helps in giving bonuses or improving training.

Challenges of Standard Allowed Minutes

While SAM is useful, it also has some downsides. Not everything works perfectly every time.

Everyone Works Differently

Not all workers are the same. Some work faster, and some slower. Even if they follow the same steps, their speed might differ. SAM is based on an average worker, but real people can vary a lot. That’s why some people may feel pressure if they always take longer.

Machines Don’t Always Help

In theory, machines make work faster. But if a machine breaks down or slows down, the SAM becomes unrealistic. Delays in tools or equipment are not always predictable. This can mess up production planning and stress out workers.

Tasks May Change Over Time

Today, stitching a shirt may take 6 minutes. But what if the fabric changes or the design is updated? SAM may need to be recalculated. If companies forget to update the SAM, it can lead to wrong planning and unfair treatment of workers.

Where Is Standard Allowed Minutes Used Most?

Standard Allowed Minutes are used heavily in industries where mass production happens. This includes:

- Garment and textile factories

- Footwear manufacturing

- Automobile assembly lines

- Electronics production

- Furniture manufacturing

In the United States, SAM is a big part of lean manufacturing and Six Sigma systems. It helps in reducing waste and improving quality control. Businesses use SAM to stay competitive and deliver on time.

The Bottom Line

Understanding Standard Allowed Minutes is like having a secret recipe for running a business smoothly. It tells you how long something should take, helps plan work better, and makes sure workers are treated fairly. While it’s not a perfect system, SAM is very helpful when used right.

Whether you’re running a factory or just learning how big businesses work, knowing about SAM gives you a new way to look at time, work, and fairness. It’s not just about counting minutes — it’s about respecting effort and improving performance.